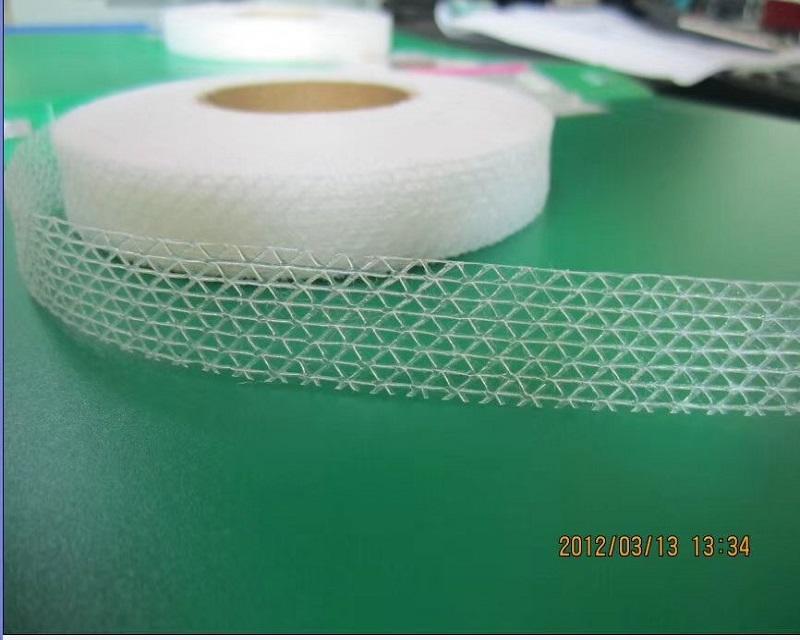

Seam Bonding: Hot melt adhesive netting is commonly used for bonding seams in garments, replacing traditional sewing methods. This application provides a sleek, flat seam finish without the need for stitching, resulting in reduced bulkiness and enhanced comfort for the wearer.

Hemming: In addition to seam bonding, hot melt adhesive netting is utilized for hemming garments, such as trousers, skirts, and dresses. It offers a secure bond while maintaining flexibility and preventing fraying, contributing to a neat and durable finish.

Applique Attachment: Hot melt adhesive netting is employed for attaching decorative appliques, patches, or embellishments onto garments. This method allows for precise positioning and secure bonding without visible stitching, enhancing the aesthetic appeal of the garment.

Fusing Interfacings: Interfacings play a crucial role in providing structure and support to various garment components, such as collars, cuffs, and waistbands. Hot melt adhesive netting is used for fusing interfacings onto fabric layers, ensuring a strong bond and maintaining the desired shape and stability.

Patchwork and Quilting: In patchwork and quilting projects, hot melt adhesive netting serves as a convenient alternative to traditional basting or pinning methods. It allows quilters to temporarily adhere fabric pieces in place before stitching, facilitating accurate alignment and preventing shifting during sewing.

Repair and Alterations: Hot melt adhesive netting is utilized in garment repair and alteration services to mend tears, secure loose seams, and reinforce weak areas. It provides a quick and effective solution for minor repairs, extending the lifespan of garments and minimizing waste.

Custom Apparel Production: Manufacturers of custom apparel, such as uniforms, costumes, and sportswear, rely on hot melt adhesive netting for various assembly tasks. It enables efficient bonding of fabric components, customization of designs, and rapid production turnaround times.

Lingerie and Intimate Apparel: Hot melt adhesive netting is employed in the production of lingerie and intimate apparel for seam bonding, elastic attachment, and embellishment applications. Its lightweight and discreet nature make it ideal for delicate lingerie fabrics and seamless designs.

Operating Temperature Range: Assess the temperature range in which the adhesive will be exposed during its service life. Some applications may involve extreme temperatures, such as automotive interiors subjected to high temperatures in summer or outdoor construction materials exposed to freezing temperatures in winter. Select an adhesive with a broad operating temperature range that can withstand fluctuations without compromising bond integrity.

Peak Temperature Exposure: Determine the maximum temperature the adhesive will encounter during processing, transportation, or use. This includes considering factors such as hot-melt application temperatures, heat generated during manufacturing processes, or exposure to heat sources in end-use environments. Choose an adhesive with sufficient heat resistance to maintain bond strength and integrity under peak temperature conditions.

Heat Aging and Long-Term Stability: Evaluate the adhesive's resistance to heat aging and long-term exposure to elevated temperatures. Over time, prolonged exposure to heat can degrade adhesive properties, leading to bond failure, reduced adhesion strength, or changes in physical characteristics. Select adhesives with proven heat aging resistance and long-term stability to ensure reliable performance over the expected service life of the bonded assembly.

Thermal Cycling: Consider the potential for thermal cycling or temperature fluctuations in the application environment. Thermal cycling, which involves repeated exposure to alternating high and low temperatures, can subject the adhesive bond to mechanical stress and thermal expansion/contraction cycles, leading to bond failure or delamination. Choose adhesives with excellent thermal cycling resistance to maintain bond integrity under dynamic temperature conditions.

Compatibility with Substrate Materials: Ensure that the adhesive's temperature resistance is compatible with the temperature limits of the bonded substrate materials. Mismatched temperature resistance between the adhesive and substrates can lead to bond failure, substrate damage, or dimensional changes in the bonded components. Select adhesives that offer compatible temperature resistance with all components of the assembly to ensure robust and durable bonds.

Application Method and Dwell Time: Consider the adhesive's temperature requirements during application, including melt temperature, dwell time, and cooling rate. Proper control of these parameters is essential to achieve optimal bonding performance and ensure uniform adhesive distribution and penetration into substrate surfaces. Adhesives with adjustable melt viscosity and rapid set times can enhance processing efficiency and bond quality in temperature-sensitive applications.

Testing and Validation: Conduct thorough testing and validation of the adhesive's temperature resistance properties under simulated or real-world conditions relevant to the application. This may include accelerated aging tests, thermal cycling tests, heat exposure tests, and performance evaluations under extreme temperature conditions. Comprehensive testing helps verify the adhesive's suitability and reliability for the intended application requirements.

浙公网安备 33048202000557号

浙公网安备 33048202000557号