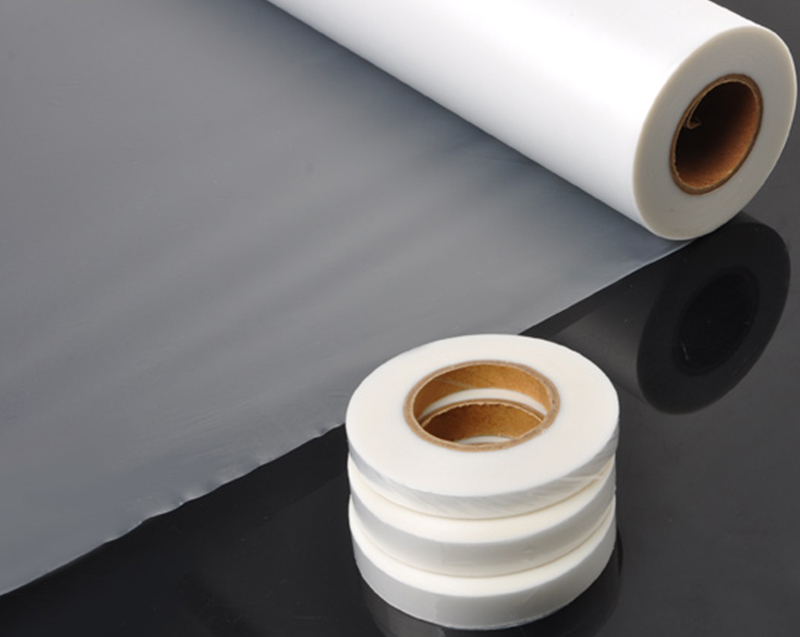

Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

When discussing the properties of specialized adhesive tapes, one of the most critical factors is their temperature resistance. This is especially true for HDPE film tape, a versatile product used in a wide range of industrial and commercial applications. Understanding its thermal performance is key to selecting the right tape for the job, ensuring both its adhesive bond and physical integrity hold up under environmental stress.

Temperature resistance isn't a simple on/off switch; it refers to the range of temperatures a material can withstand without undergoing significant degradation. For HDPE film tape, this involves two key areas:

High-Temperature Resistance: This is the maximum temperature the tape can tolerate, often for a limited duration, before its adhesive softens or melts and the film itself begins to deform or shrink.

Low-Temperature Resistance: This refers to the minimum temperature at which the tape's adhesive remains flexible and tacky, and the film does not become brittle or lose its structural integrity.

The thermal properties of HDPE film tape are inherently linked to the base material itself: High-Density Polyethylene (HDPE). HDPE is a thermoplastic polymer known for its durability and strong chemical resistance.

While specific values can vary between manufacturers and product formulations, a general range for HDPE film tape is:

Service Temperature: A typical continuous operating temperature range is from -40°F to 180°F (-40°C to 82°C). This is the range where the tape performs optimally for extended periods.

Short-Term Temperature: Some specialized formulations may withstand higher temperatures for brief periods, sometimes up to 200°F (93°C), without immediate failure.

The adhesive also plays a crucial role in the tape's temperature resistance. The most common adhesives used with HDPE film tape are acrylic-based, which offer good resistance to high temperatures and UV exposure. In colder conditions, these adhesives maintain their tack and won't become brittle, a common issue with other adhesive types.

The thermal stability of HDPE film tape is critical for many applications:

Construction and HVAC: In duct sealing or pipe wrapping, the tape needs to withstand seasonal temperature fluctuations, from scorching summer heat to freezing winter cold, without peeling or losing its seal.

Greenhouse and Agriculture: For repairing greenhouse covers or splicing films, the tape must resist both extreme solar heat and chilly nights. A tape with poor temperature resistance will fail quickly, compromising the structure's integrity.

Industrial and Manufacturing: In machinery or electronics, where components can generate heat, the HDPE film tape must maintain its insulating or bonding properties without softening.

Transportation: For vehicle manufacturing or repair, the tape must endure a wide range of temperatures, from a hot engine compartment to a frozen outdoor environment, ensuring the materials it's holding together remain secure.

To maximize the thermal performance of your HDPE film tape, consider these best practices:

Clean and Dry Surface: The bonding surface must be free of dust, grease, and moisture. Contaminants can compromise the adhesive's ability to create a strong bond, especially under temperature stress.

Proper Pressure: Applying firm and uniform pressure during installation ensures the adhesive makes full contact with the surface, maximizing its bond strength and thermal resistance.

Match the Tape to the Application: Always choose a tape with a temperature range that comfortably exceeds the expected operational temperatures of your project.

In summary, when specifying a HDPE film tape for a project, its temperature resistance is a primary concern. Choosing a high-quality product with the right thermal properties ensures long-lasting performance and reliability, regardless of the environmental challenges it faces.