The aspects of strength and durability concerning Hot Melt Adhesive Elastic Mesh Film

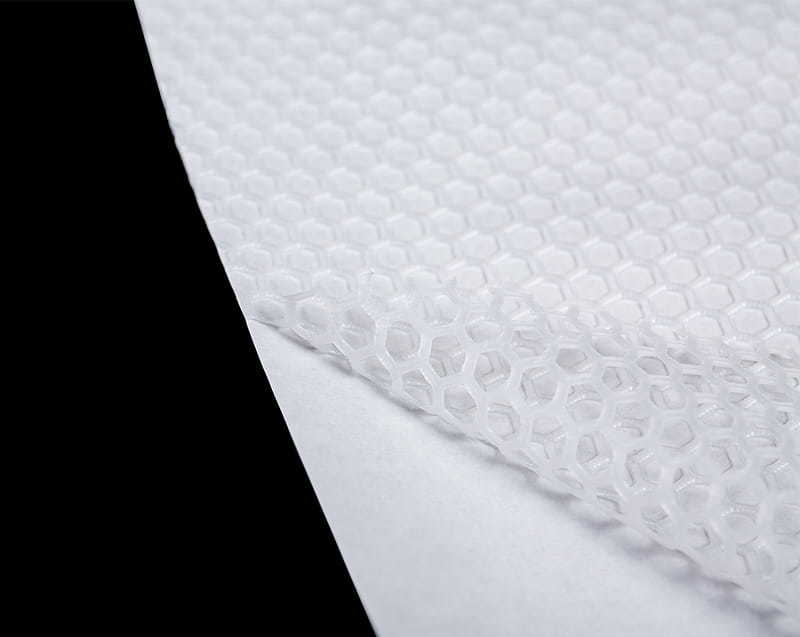

Tensile Strength: Hot Melt Adhesive Elastic Mesh Film typically exhibits excellent tensile strength, which is the ability to withstand pulling forces without breaking. This property ensures that the film can withstand stretching during application or usage without tearing apart, maintaining its structural integrity.

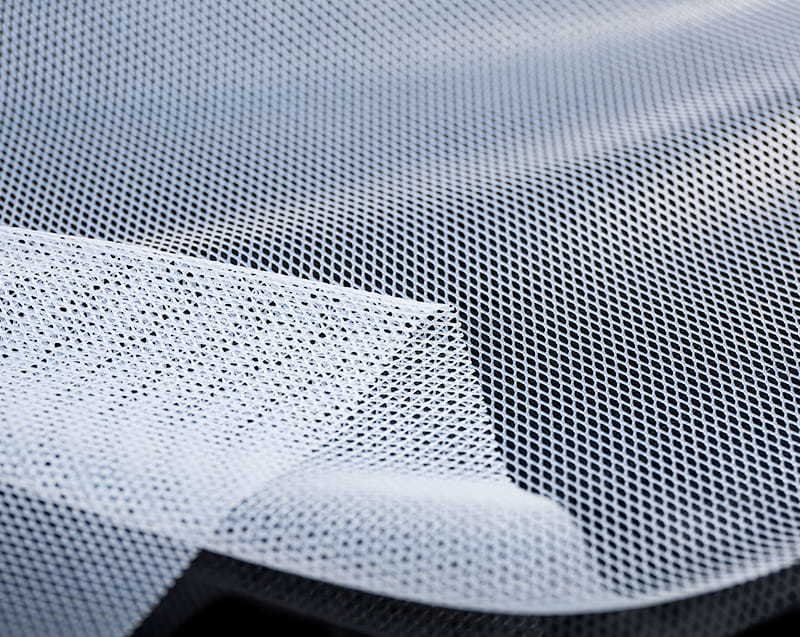

Flexibility: While being strong, the film retains flexibility, allowing it to bend and conform to various shapes without losing its adhesive properties. This flexibility is crucial in applications where the substrate or the bonded materials undergo deformation or movement, such as in flexible packaging or textile lamination.

Impact Resistance: The film's durability is reflected in its resistance to impact and mechanical stress. It can withstand handling during manufacturing, transportation, and application processes without sustaining damage, ensuring reliable performance throughout its lifecycle.

Abrasion Resistance: In applications where the film comes into contact with abrasive surfaces or undergoes frictional forces, its abrasion resistance becomes significant. A durable outer layer protects the adhesive and mesh structure from wear and tear, maintaining adhesion and functionality over time.

Environmental Resistance:

Hot Melt Adhesive Elastic Mesh Film is often designed to withstand exposure to environmental factors such as moisture, UV radiation, and temperature fluctuations. This resistance ensures that the adhesive properties remain stable, and the film retains its strength and elasticity even in challenging conditions.

Longevity: The combination of strength and durability contributes to the longevity of Hot Melt Adhesive Elastic Mesh Film. It can remain securely bonded to substrates for extended periods without deteriorating, making it suitable for long-term applications such as construction, automotive assembly, or outdoor signage.

Chemical Resistance: Certain formulations of the film may offer resistance to chemicals and solvents, further enhancing its durability in environments where exposure to such substances is expected. This property prevents degradation of the adhesive and ensures reliable bonding in industrial settings.

Adhesive Integrity: Despite exposure to various stressors, the adhesive layer maintains its integrity, firmly bonding the mesh to the substrate. This aspect is crucial for applications where strong and reliable adhesion is paramount, such as in aerospace, electronics, or medical device assembly.

Hot Melt Adhesive Elastic Mesh Film offers several advantages for outdoor use

Weather Resistance: Hot Melt Adhesive Elastic Mesh Film is engineered to withstand exposure to sunlight (UV radiation), rain, snow, and other weather conditions without degrading or losing its adhesive properties. This makes it ideal for outdoor signage, banners, and architectural cladding, where durability and longevity are essential.

Waterproofing and Sealing: The film's elastic properties allow it to create watertight seals when applied to joints, seams, or gaps in outdoor structures. This is particularly important for construction projects, where preventing water ingress is critical to maintaining the integrity of buildings, bridges, and other infrastructure.

Expansion and Contraction: In outdoor environments, materials are subjected to temperature variations that cause them to expand and contract. Hot Melt Adhesive Elastic Mesh Film can accommodate these dimensional changes, preventing delamination or failure of bonded surfaces. This is crucial for applications such as outdoor furniture, where wood or metal components may expand or contract with changes in temperature and humidity.

UV Resistance: Some formulations of Hot Melt Adhesive Elastic Mesh Film are specifically designed to resist UV degradation, ensuring that bonded surfaces remain stable and secure over time. This UV resistance is particularly important for outdoor applications exposed to direct sunlight, such as solar panels, outdoor lighting fixtures, or automotive exterior trim.

Landscaping and Horticulture: In landscaping and horticulture, Hot Melt Adhesive Elastic Mesh Film can be used to create durable and weather-resistant structures such as artificial turf seams, greenhouse coverings, or landscape edging. Its flexibility and resistance to moisture make it well-suited for these applications, where materials are exposed to the elements for extended periods.

Automotive and Transportation: In the automotive industry,

Hot Melt Adhesive Elastic Mesh Film is used for exterior applications such as automotive trim, decals, and protective films. Its ability to withstand exposure to sunlight, moisture, and temperature variations ensures that bonded surfaces remain secure and visually appealing even in harsh outdoor environments.

Marine Applications: Hot Melt Adhesive Elastic Mesh Film is also used in marine applications where materials are exposed to saltwater, humidity, and constant movement. It can be applied to boat hulls, deck seams, and marine accessories to provide a durable and waterproof seal that withstands the rigors of marine environments.

浙公网安备 33048202000557号

浙公网安备 33048202000557号