How does the flexibility of paper substrate affect the application and performance of hot melt adhesive webs?

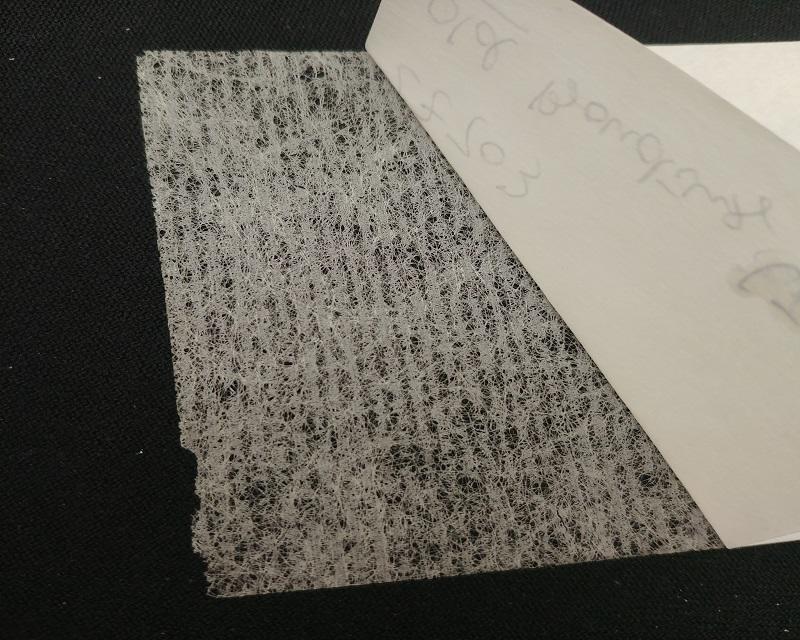

Flexibility refers to the ability of a material or bonded assembly to bend, stretch, or deform without breaking or losing its structural integrity. In the context of hot melt adhesive web and paper substrates, flexibility plays a critical role in determining the durability and usability of the bonded product. The following is the effect of flexibility on

Hot Melt Adhesive Web With Paper bonding properties:

Handling and Processing: Flexible bonds are essential for materials that undergo bending or folding during handling, processing, or use. For example, packaging materials, such as cartons or envelopes, often require flexible adhesive bonds to withstand frequent manipulation without failure.

Conformability: Flexible adhesive bonds can conform to irregular or curved surfaces, ensuring intimate contact between the adhesive and substrate. This is particularly important for applications where the substrate has varying contours or shapes, such as in the fabrication of molded paper products or three-dimensional packaging.

Tensile Strength: Flexibility is closely related to tensile strength, which measures the ability of a material to withstand pulling forces without breaking. Flexible adhesive bonds distribute stress more evenly across the bonded interface, reducing the likelihood of bond failure under tension. This is crucial for applications where the bonded assembly is subjected to mechanical forces, such as in bookbinding or product packaging.

Impact Resistance: Flexible adhesive bonds can absorb energy and dissipate stress when subjected to sudden impacts or shocks. This property is particularly important for packaging materials or products that may be handled roughly during transit or storage. Flexible bonds help prevent delamination or separation of the adhesive interface when subjected to impact loads.

Temperature Resistance: Flexibility can also influence the adhesive bond's ability to withstand temperature fluctuations without losing adhesion or becoming brittle. Flexible bonds maintain their integrity over a wide range of temperatures, ensuring consistent performance in both hot and cold environments.

Long-Term Durability: Flexible adhesive bonds are often more resistant to fatigue and degradation over time, prolonging the lifespan of the bonded assembly. This is critical for applications where the bonded product is expected to endure repeated stress cycles or environmental exposure without failure.

Effect of temperature fluctuations on hot melt adhesive web with paper

Temperature fluctuations can have a significant impact on the performance and stability of hot melt adhesive web with paper. Here's how temperature variations can affect the adhesive bond:

Bond Strength:

Temperature fluctuations can cause the hot melt adhesive to expand and contract, potentially affecting the integrity of the bond. Higher temperatures may soften the adhesive, leading to increased bond strength, while lower temperatures can make the adhesive more brittle, reducing bond strength.

Rapid changes in temperature can also induce thermal stress within the bonded assembly, which may weaken the adhesive bond over time.

Viscosity and Flow Properties:

Hot melt adhesives are designed to melt and flow when heated, allowing them to form strong bonds with substrates. Temperature fluctuations can alter the viscosity and flow characteristics of the adhesive, affecting its ability to wet out and penetrate the paper substrate.

At higher temperatures, the adhesive may become too fluid, leading to excessive adhesive penetration or bleed-through. Conversely, lower temperatures can cause the adhesive to solidify prematurely, resulting in incomplete wetting and poor bonding.

Adhesive Activation and Cure:

Hot melt adhesives require specific temperature ranges for proper activation and curing. Temperature fluctuations outside these ranges can interfere with the adhesive's ability to form a strong bond.

Insufficient heating may result in inadequate adhesive activation, leading to weak or unstable bonds. Conversely, overheating can degrade the adhesive or cause it to char, compromising bond performance.

Dimensional Stability:

Temperature changes can induce dimensional changes in both the adhesive and paper substrate, potentially affecting the fit and alignment of bonded components. These dimensional variations may lead to stress build-up within the bonded assembly, increasing the risk of bond failure or delamination.

Environmental Exposure:

Temperature fluctuations can exacerbate the effects of environmental exposure on the bonded assembly. For example, repeated cycles of heating and cooling combined with moisture ingress can accelerate degradation of the adhesive bond, leading to premature failure.

Use adhesive formulations specifically designed to withstand the expected temperature ranges and environmental conditions of the application.

Optimize adhesive application parameters, such as temperature, dwell time, and pressure, to ensure proper bonding and cure.

Choose paper substrates with thermal stability and dimensional integrity to minimize the risk of distortion or warping.

Implement proper storage and handling practices to minimize exposure to temperature extremes during transportation, storage, and processing.

By addressing these factors, manufacturers can enhance the performance and durability of hot melt adhesive bonds with paper substrates, even in the face of temperature fluctuations.

浙公网安备 33048202000557号

浙公网安备 33048202000557号