Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

In the dynamic world of textiles and fabrics, the demand for strong, lightweight, and versatile bonding solutions is constantly growing. Traditional methods like sewing, stitching, and liquid glues are being challenged by more efficient and innovative technologies. One such groundbreaking solution is the Hot Melt Adhesive Web.

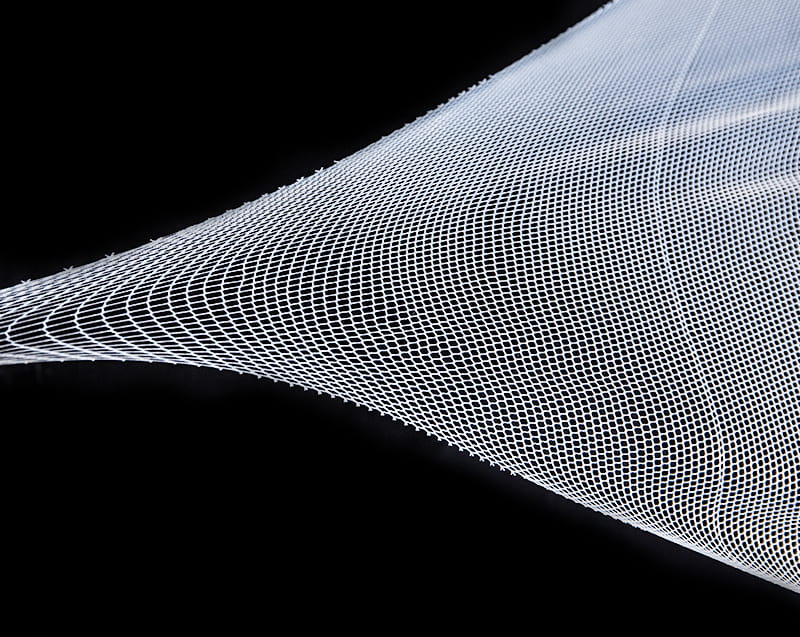

A Hot Melt Adhesive Web is a non-woven, net-like film made from thermoplastic polymers. Unlike traditional adhesives that are liquid or solid in their natural state, the web is a dry, porous material that resembles a fine spiderweb or mesh. It is typically supplied on a roll, often with a release liner for easy handling.

The bonding process is remarkably simple yet highly effective. The adhesive web is placed between two layers of fabric. When heat and pressure are applied—usually via a heat press, lamination machine, or even a household iron—the web melts and permeates the fibers of the textiles. As it cools, it solidifies, creating a durable and permanent bond that is both flexible and invisible.

The widespread adoption of Hot Melt Adhesive Web in the textile industry is due to its unique combination of properties:

Breathability and Flexibility: The web's porous structure ensures that the bonded fabric remains breathable, unlike liquid adhesives that can create a solid, impermeable layer. This is crucial for performance apparel, footwear, and medical textiles.

Lightweight and Clean: Because it's a dry material, there is no messy residue, curing time, or solvent required. The result is a clean, lightweight bond that doesn't add bulk or change the hand-feel of the fabric.

Uniform Application: The web format guarantees a consistent and even layer of adhesive across the entire bonding area, eliminating lumps or uneven spots that can occur with liquid glues.

Strong and Durable Bond: The bond created by the Hot Melt Adhesive Web is extremely strong and resilient, able to withstand washing, dry cleaning, and general wear and tear without delaminating.

Versatility: It can bond a wide range of materials, from natural fibers like cotton and wool to synthetics like polyester, nylon, and non-wovens, making it suitable for a diverse set of applications.

The versatility of Hot Melt Adhesive Web has made it a go-to solution for a variety of textile applications:

Apparel and Performance Wear: It is used to bond hems, seams, and decorative elements, especially in high-performance sportswear and outdoor gear where flexibility and strength are paramount. It's also ideal for creating "no-sew" apparel, leading to a cleaner aesthetic.

Footwear: From bonding uppers to linings to creating structural integrity, the web adhesive is a staple in modern shoe manufacturing, where it offers a lightweight and durable alternative to traditional stitching.

Automotive Textiles: In car interiors, it is used for laminating fabrics to foam or plastic substrates for headliners, door panels, and seat covers.

Medical and Hygiene: The breathability and non-toxic nature of the web make it perfect for bonding layers in surgical gowns, bandages, and other medical textiles.

Home Furnishings: It provides a strong, invisible bond for upholstery, curtains, and other home décor items, simplifying the manufacturing process.

Selecting the correct Hot Melt Adhesive Web is critical for a successful application. Key factors to consider include:

Polymer Type: Different polymers like polyamide (PA), polyurethane (PU), and co-polyester (CoPES) offer varying properties in terms of melting point, washability, and flexibility. For example, PU is known for its excellent flexibility, making it ideal for elastic fabrics.

Melting Temperature: Ensure the adhesive's melting point is compatible with the fabrics you are bonding to prevent damage.

Weight/Thickness (GSM): The gram per square meter (GSM) of the web determines the amount of adhesive applied. A higher GSM provides a stronger bond but may reduce flexibility and breathability.

Release Liner: For manufacturing at scale, a high-quality release liner is essential for easy unwinding and application.

In conclusion, the Hot Melt Adhesive Web has emerged as a game-changer for textile and fabric manufacturers. Its ability to create strong, durable, and discreet bonds while maintaining the integrity and aesthetics of the material makes it an indispensable tool for innovation. As the industry continues to push the boundaries of design and functionality, this advanced adhesive will undoubtedly play a central role in shaping the future of textile manufacturing.