The hot melt adhesive web has proven to be an indispensable material, particularly in high-performance applications where uniform adhesive distribution, breathability, and process efficiency are critical. Beyond general textiles, its structured format provides specific technical advantages that are revolutionizing two demanding fields: advanced filtration and composite structure manufacturing.

Precision Bonding in Air and Fluid Filtration

In the filtration industry, the performance of the filter is directly tied to the integrity and consistency of the media structure. The hot melt adhesive web addresses key manufacturing challenges in this area:

- Pleat Stabilization: A primary use is to bond and stabilize pleats in air, oil, fuel, and HVAC (Heating, Ventilation, and Air Conditioning) filters. The adhesive web is positioned between filter media layers before pleating. When heated, it secures the pleats uniformly, preventing shifting and maintaining the precise geometry necessary for optimal filtration efficiency and airflow.

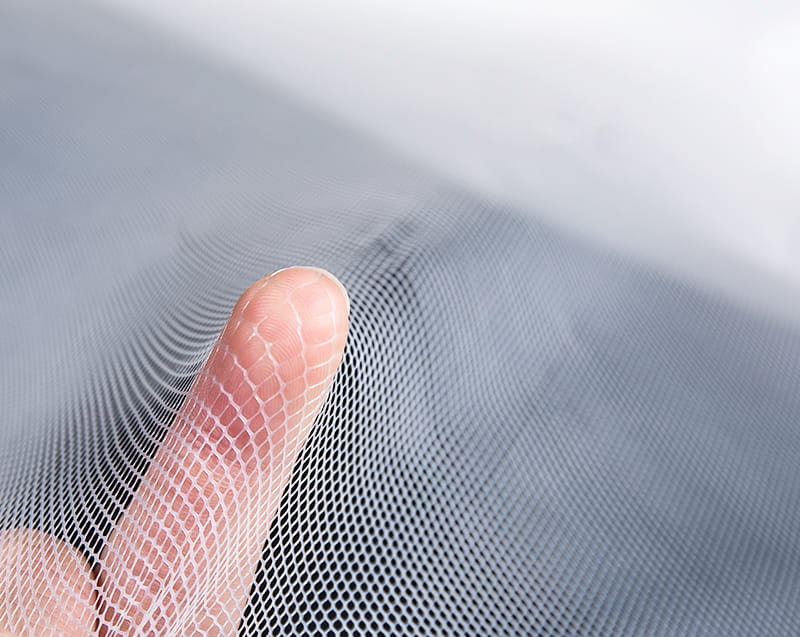

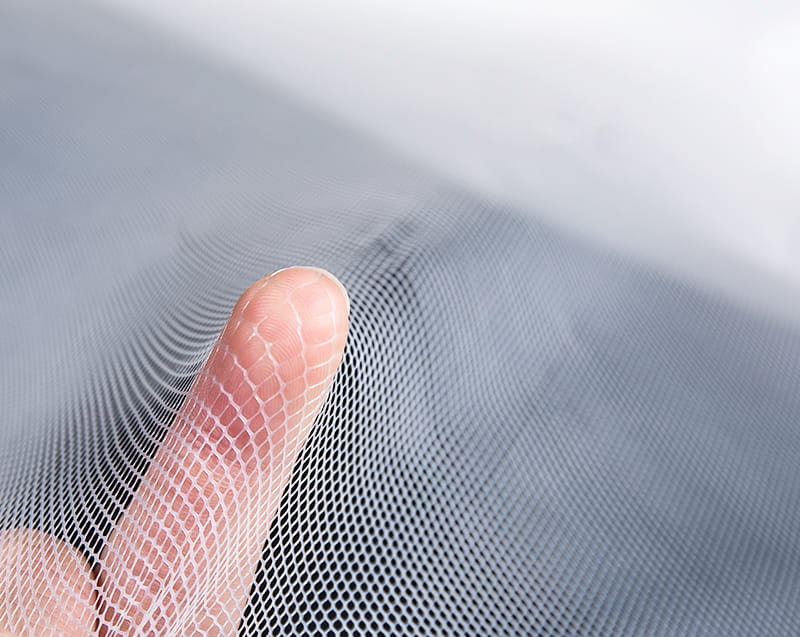

- Media Lamination: Filters often consist of multiple layers of specialized media (e.g., melt-blown non-wovens, spunbond fabrics, fiberglass). The adhesive web allows for the lamination of these dissimilar materials without blocking the microscopic pores of the media. The open-mesh structure ensures a strong bond while preserving the required breathability and porosity.

- Zero-VOC Solution: The use of hot melt adhesive web is favored due to its 100% solid content, eliminating the need for solvents. This is critical in sensitive applications like cabin air filters and medical filters, where low Volatile Organic Compound (VOC) emissions are a strict requirement for health and regulatory compliance.

Lightweighting and Durability in Automotive Composites

The automotive sector is increasingly leveraging the hot melt adhesive web for interior assembly and acoustic management due to its ability to create strong, lightweight bonds with low emissions.

- Headliner and Interior Trim Lamination: The web is widely used to laminate textile or foam coverings onto rigid substrates for components like headliners, door panels, and parcel shelves. It activates quickly under heat and pressure, enabling high-speed manufacturing lines.

- Acoustic Insulation: In noise, vibration, and harshness (NVH) reduction applications, the web bonds various sound-dampening materials like acoustic felts and foams. The lightweight, uniform adhesion helps create multi-layer composites that effectively absorb and block sound without adding significant vehicle mass—a key focus for improving fuel economy and electric vehicle range.

- Thermoformability: Adhesives used in the automotive industry must often allow for thermoforming, where the laminated composite is molded into complex, three-dimensional shapes. The specific polymer chemistry of the hot melt adhesive web (often Polyamide or Polyester) is engineered to soften during molding and re-solidify, holding the final shape with excellent temperature and aging resistance.

Advanced Polymer Chemistries

The performance of the hot melt adhesive web depends heavily on the chosen polymer:

| Polymer Type |

Key Features |

Common Applications |

| Polyamide (PA) |

High chemical and heat resistance, strong adhesion to polar materials. |

Automotive headliners, high-temperature filtration. |

| Polyester (PES) |

Excellent washing/dry-cleaning resistance, good thermal stability. |

Performance apparel, general lamination. |

| Polyurethane (PU) |

High flexibility, toughness, and superior soft-feel for textiles. |

Technical textiles, medical gowns, flexible foams. |

The evolution toward reactive hot melt adhesive webs—such as those based on moisture-curing Polyurethane—is further expanding the material’s potential, providing a final cross-linked bond that offers even greater structural integrity and environmental resistance.