Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

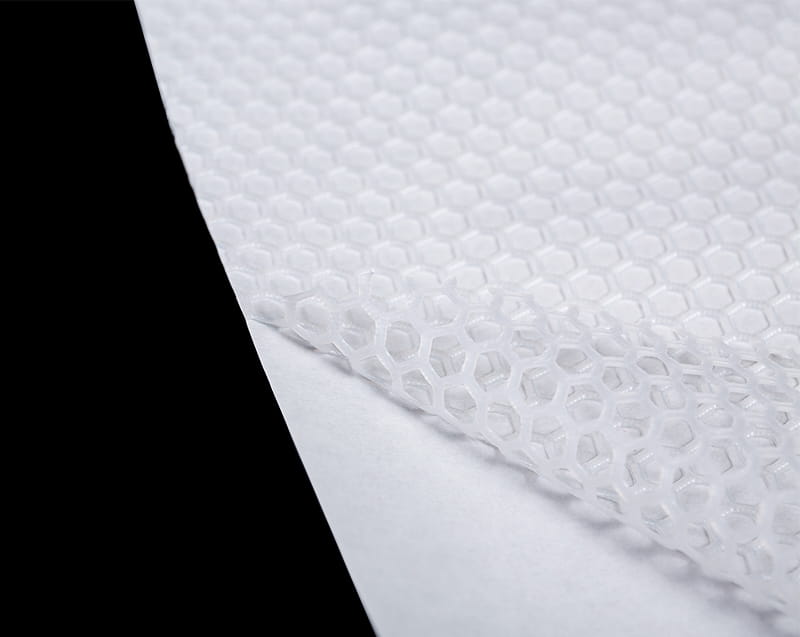

Hot Melt Adhesive Web is a special form of hot melt adhesive made into a fibrous or web-like structure, widely used in various fields such as textiles, automotive, medical, and footwear. Its core advantages lie in its thinness, uniformity, environmental friendliness, solvent-free nature, and excellent bonding performance. To fully leverage these advantages, a deep understanding of a key physical property of Hot Melt Adhesive Web—its melting point—is crucial.

The melting point of a hot melt adhesive web refers to the specific temperature required for the adhesive to transition from a solid to a liquid state. This temperature isn't a single value but rather a melting temperature range. This is because hot melt adhesives are typically a mixture of various polymers, resins, tackifiers, and waxes, with each component having its own unique melting characteristics. Therefore, when we talk about the melting point, we are referring more to the temperature range where the mixture begins to soften and eventually fully melts.

Understanding this temperature range is critical for practical applications:

Softening Point: This is the temperature at which the material begins to soften and become pliable. Below this temperature, the hot melt adhesive web remains solid.

Melting Point (Final Melting Point): This is the temperature at which the material completely transforms into a liquid with good flowability. The adhesive web must reach this temperature to fully wet the surfaces of the substrates and form an effective bond.

The melting point of a hot melt adhesive web is influenced by its chemical composition and molecular structure. The main factors include:

Polymer Base Material Type: This is the most critical factor determining the melting point. Common base materials include:

EVA (Ethylene-vinyl acetate copolymer): Has a lower melting point, typically between 80℃ and 120℃.

PES (Polyester): Has a higher melting point, usually between 110℃ and 180℃.

PA (Polyamide): Has the highest melting point, typically between 120℃ and 190℃.

TPU (Thermoplastic polyurethane): Has a relatively moderate melting point but offers excellent elasticity, with a range usually between 100℃ and 160℃.

Tackifiers and Plasticizers: These additives improve the adhesive properties of the hot melt adhesive while also affecting its melting point and flowability.

Molecular Weight Distribution: The wider the molecular weight distribution of the polymer, the broader its melting temperature range will be.

Understanding the melting point of a Hot Melt Adhesive Web and selecting the appropriate melting temperature based on its characteristics is key to ensuring bonding quality and production efficiency.

Bonding Strength: The melting temperature must be high enough to ensure the adhesive web fully melts and sufficiently wets the substrate surfaces to form a strong bond. If the temperature is too low, the adhesive web will not penetrate effectively, leading to a weak bond or localized delamination.

Substrate Protection: In many applications, such as textiles and medical supplies, the substrates being bonded are sensitive to temperature. If the melting temperature is too high, it may cause the substrate to discolor, deform, or even be damaged. Therefore, it is crucial to select a hot melt adhesive web with a melting point that matches the heat resistance of the substrate.

Production Efficiency: The melting temperature directly affects the heating and cooling times on the production line. Choosing a hot melt adhesive web with a lower melting point can shorten the production cycle and increase efficiency. However, for certain high-temperature applications like automotive interiors, a hot melt adhesive web with a higher melting point is necessary to ensure the bond remains strong in a hot environment.

Operational Safety: Controlling the melting temperature not only ensures product quality but also enhances operational safety by preventing thermal damage or equipment failure caused by excessive heat.

Measurement Methods: Common methods for measuring the melting point of hot melt adhesive web are Differential Scanning Calorimetry (DSC) and hot stage microscopy. These methods can accurately measure the endothermic peak of the material, thereby determining its melting temperature range.

Selection Recommendations:

Based on the Adhered Substrate: Prioritize selecting a Hot Melt Adhesive Web with a melting point that is lower than or slightly below the maximum temperature resistance of the substrate.

Based on the Application Environment: If the product will be used in a high-temperature environment, a hot melt adhesive web with a higher melting point, such as PA or high-melting-point PES, should be chosen.

Based on Production Conditions: Consider the heating and cooling capabilities of the production line and select a Hot Melt Adhesive Web with a melting temperature that is compatible with your existing equipment.

In conclusion, the melting point of a Hot Melt Adhesive Web is one of its core performance indicators. A thorough understanding and correct application of this characteristic can help companies optimize their production processes, improve product quality, and ultimately stand out in a competitive market.