Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

There are many types of clothing fabrics, including traditional cotton and linen fabrics, silk fabrics, polyester, spandex, nylon and other chemical fiber materials, or blended fabrics.

For fabrics with different proportions and different compositions, the surface properties are also different. Different fabrics have relatively different requirements for the performance of hot melt adhesive films, which puts forward higher customization requirements for the development of hot melt adhesive films.

Different fabrics have relatively different requirements for the performance of hot melt adhesive films, which puts forward higher customization requirements for the development of hot melt adhesive films.

The application of hot melt adhesive film in underwear stems from people's pursuit of beauty. I don't know when the concept of traceless became popular.

The hot melt adhesive film used on the edges of cup cups, underwear waistbands, and trouser legs needs to have very good softness and outstandingly good elasticity so that the underwear can highlight the wearer's body lines while reducing the number of clothes and users. The friction of the body makes wearing more natural, showing the charm, and enjoying the comfort without any trace!

Wearing boat socks with autumn shoes can release the beauty of women's feet and is very popular among fashionable women! The use of hot melt adhesive film is also indispensable.

Hot-melt adhesive film is mainly used for the edge of boat socks. The hot-melt adhesive film is required to be firmly bonded and at the same time have good elasticity, good resilience and washability, making the socks durable!

Traditional reflective clothing mainly uses seam technology to sew the reflective parts to the clothing. The application of hot melt adhesive film on reflective clothing mainly replaces the seam technology. The reflective heat-adhesive film with adhesive backing is directly pressed onto the clothing.

The adhesive pressing process makes the reflective strips firmer on the garment and avoids the disadvantage of the seam process being non-waterproof. It also improves the overall texture of the garment and makes the reflective clothing more practical.

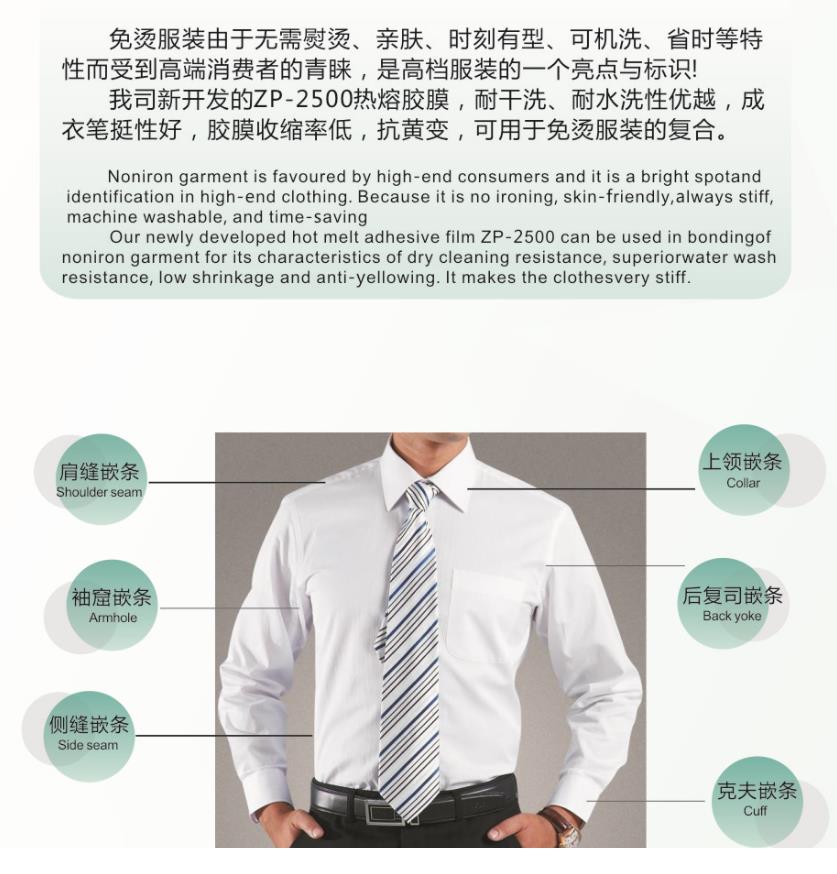

The use of hot-melt adhesive film-fitting linings on clothing collars and cuffs has gradually become a better choice for high-end no-iron shirts.

Different adhesive films can be selected depending on the corresponding fabric and effect. For example, silk fabrics generally use softer films; harder films are used in garments that require a crisp effect.

Hot melt adhesive film is mainly used to replace the sewing process in certain parts of sports and outdoor clothing, so that there is no bulge in the bonding area and the wear is more close-fitting. Hot melt adhesive film is also used on the zippers of outdoor jackets, which has a very good waterproof effect.

The application of hot melt adhesive film on epaulettes and cap badges of military uniforms involves the bonding of cloth, plastic, metal and other materials. Strong and reliable bonding strength is the primary factor.

Stretch functional fabric composite non-woven lining

The TPU polyurethane elastic non-woven lining newly developed by Pinghu Zhanpeng Hot Melt Adhesive Film Co., Ltd. is waterproof, breathable, has outstandingly good stretchability and resilience, and has 10 grams or 20 grams of single-sided or double-sided hot melt adhesive powder on the surface. In elastic functional fabric clothing, enhance the texture and elasticity of high-end functional clothing.

Founded in 2000 in Shanghai, Pinghu Zhanpeng Hot Melt Adhesive Film Co Ltd is a high-tech enterprise specializing in the production of hot melt adhesive materials. In 2006, the company built its own standardized workshop covering an area of 12,000 square meters in Zhejiang Pinghu Economic Development Zone to provide reliable guarantee for sustainable operations. The company specializes in R&D and production of hot-melt bonding material products including EVA, PA, PES, TPU, EAA, HDPE film, mesh, grille and other hot-melt adhesive materials and TPU melt-blown elastic non-woven fabrics. The products are widely used in clothing, lining fabrics, automobile interior decoration, shoe materials, furniture, filtration industry, medical dressings, building materials and other industrial fields.

Our products are exported to 32 countries and regions around the world, and we have accumulated nearly 20 years of rich experience in the field of hot melt adhesive bonding. The company adheres to the concept of "docking, innovation, and win-win" and focuses on the research, development, production and sales of "modified hot melt adhesive film". It can customize production according to customer projects and provide customers with testing and material selection, research and development, production, follow-up product after-sales and technical one-stop service.

For more information on application fields, please call 0573-8509 2050.