Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

Everyone is familiar casting hot fusible film with double-sided tape, and it is used from time to time in daily life and work. Many people will feel unfamiliar with hot melt double-sided adhesive lining. Of course, it may be used by some people, but I just don’t know what the correct name is. We are all familiar with the mention of double-sided tape. It is a convenient and fast adhesive that we may often use in daily and work. The adhesion is average, but it can basically meet the requirements of adhesion in daily life.

This kind of double-sided tape is generally not used to bond large volume or rough surface items, after all, the adhesion is limited! From the aspect of use, double-sided tape is also very convenient. Basically, it can be used after opening, without the help of other functions. Hot-melt double-sided adhesive lining can also be called hot-melt double-sided adhesive, so some people will simply refer to it as double-sided adhesive. This may be the reason why many people confuse hot-melt double-sided adhesive liners with double-sided tape.

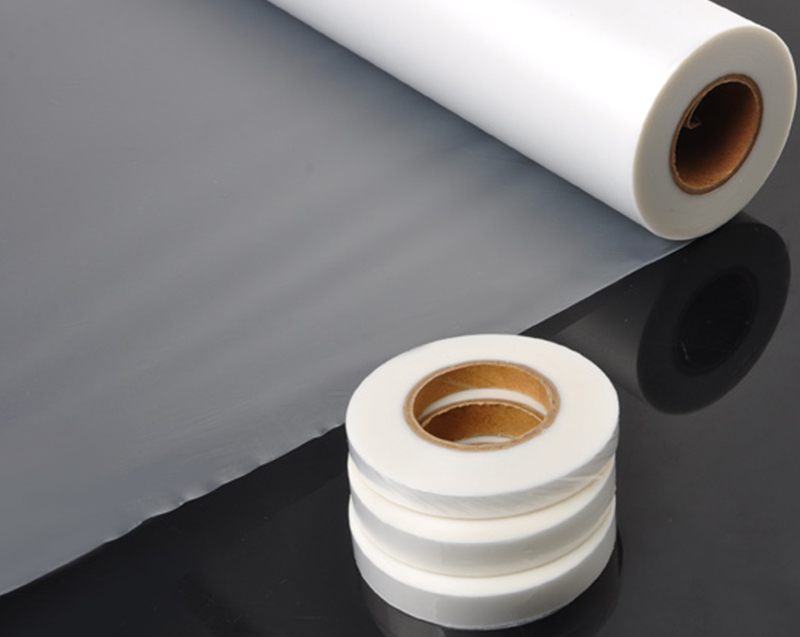

Hot-melt double-sided adhesive interlining is actually a large roll of hot-melt adhesive film or hot-melt omentum film cut into small rolls. The reason for the slitting is also to meet the use requirements of related industries, such as the seam of the clothing industry, the seam of the curtain industry, etc. The difference between hot-melt double-sided adhesive interlining and double-sided adhesive is not only discernible in appearance, but it is obviously different in applicability and use method.

Hot-melt double-sided adhesive lining is suitable for industrial production or manual manufacturing. In terms of use, some tools are required to use. After all, the hot-melt double-sided adhesive interlining needs to be heated to a certain temperature to produce adhesion. In general, the hot-melt double-sided adhesive liner and double-sided adhesive are different in many aspects such as process, manufacturing materials, bonding performance, scope of application, and methods of use. Don’t mistake the same type of adhesive because they are similar in appearance!