Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

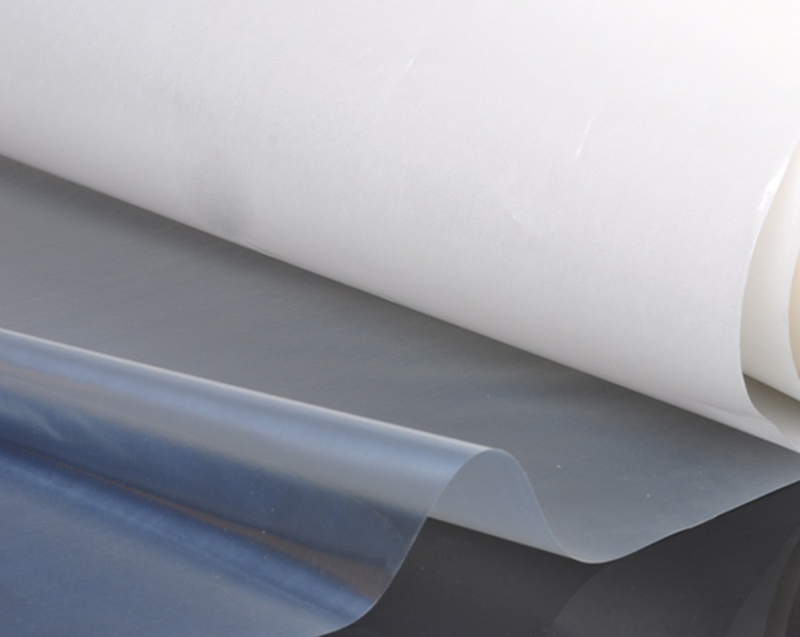

Hot melt adhesive film is a solid-state bonding medium that transitions into a liquid state when heat is applied, acting as a high-performance alternative to traditional liquid glues or spray adhesives. Unlike liquid adhesives that rely on solvent evaporation or chemical curing, these films are composed of 100% solid thermoplastic polymers. This structure ensures a uniform thickness across the entire bonding surface, eliminating the risk of "glue spots" or uneven tension that can lead to material warping. The film is typically supplied on a release paper or liner, making it easy to die-cut into specific shapes for precision manufacturing in the automotive, textile, and electronics industries.

The bonding process occurs through a cycle of melting and cooling. When the film reaches its specific melting point (Tm), it wets the substrates and flows into the microscopic pores of the material. As the heat source is removed and the temperature drops, the polymer rapidly recrystallizes, forming a strong mechanical and chemical bond. This "instant" set time is a primary driver for its use in automated assembly lines where high throughput is essential.

Selecting the correct chemical base is critical to ensuring the longevity of the bond under environmental stress. Different polymers offer varying degrees of flexibility, heat resistance, and washability.

| Polymer Type | Key Properties | Typical Applications |

| TPU (Polyurethane) | High elasticity, soft hand-feel, excellent wash resistance. | Sportswear, seamless intimate apparel, waterproof gear. |

| PO (Polyolefin) | Excellent adhesion to metals and plastics (PE/PP). | Automotive interiors, aluminum honeycomb panels. |

| PES (Polyester) | Superior dry cleaning resistance and high-temperature stability. | Interlinings, industrial filters, fabric laminations. |

| EVA | Low melting point, high cost-effectiveness. | Packaging, craft applications, foam bonding. |

Achieving a structural bond requires the precise calibration of three variables, often referred to as the "Bonding Triangle." Failure to balance these can result in delamination or thermal damage to the substrates.

The glue line temperature must exceed the melting point of the film. However, operators must account for the heat sink effect of the substrates. If bonding a thick metal plate to a fabric, the heat press temperature must be set higher to ensure the thermal energy penetrates the metal and reaches the film.

Consistent pressure ensures that the molten film is forced into the fibers or surface irregularities of the material. Insufficient pressure leads to "dry bonding," where the film sits on top of the material rather than integrating with it. Conversely, excessive pressure can squeeze the adhesive out of the edges, resulting in a starved joint.

This is the duration for which the heat and pressure are applied. Dwell time must be long enough for the entire thickness of the film to melt, but short enough to prevent the degradation of heat-sensitive materials like synthetic leathers or thin films.

Transitioning to hot melt film offers several manufacturing and environmental advantages that align with modern ESG (Environmental, Social, and Governance) goals:

Even with high-quality film, bonding issues can arise due to surface contamination or material incompatibility. When encountering delamination, consider the following technical checks: