Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

Hot Melt Adhesive Film (HMAF) represents a significant advancement in bonding technology, offering manufacturers a clean, solvent-free, and efficient method for joining a vast array of materials. As a key component in numerous industrial and consumer applications, the versatility and performance characteristics of HMAF have cemented its status as a vital material in modern production processes.

A Hot Melt Adhesive Film is essentially a thermoplastic polymer formulated into a solid, dry film at room temperature. The adhesive requires heat activation to transition from a solid to a molten state, allowing it to wet the substrates and create a bond upon cooling. Unlike traditional liquid adhesives, HMAF offers several inherent advantages:

The films are typically supplied on a release liner in roll form and can be easily die-cut into precise shapes, offering exceptional control over the application area and amount of adhesive used. Common chemistries utilized include polyamides, polyesters, polyurethanes, polyolefins (like EVA and metallocene polyolefins), and various co-polymers, each selected for specific end-use requirements such as temperature resistance, flexibility, and adhesion to challenging substrates.

The unique properties of Hot Melt Adhesive Film allow it to serve as a robust bonding solution across several key industries:

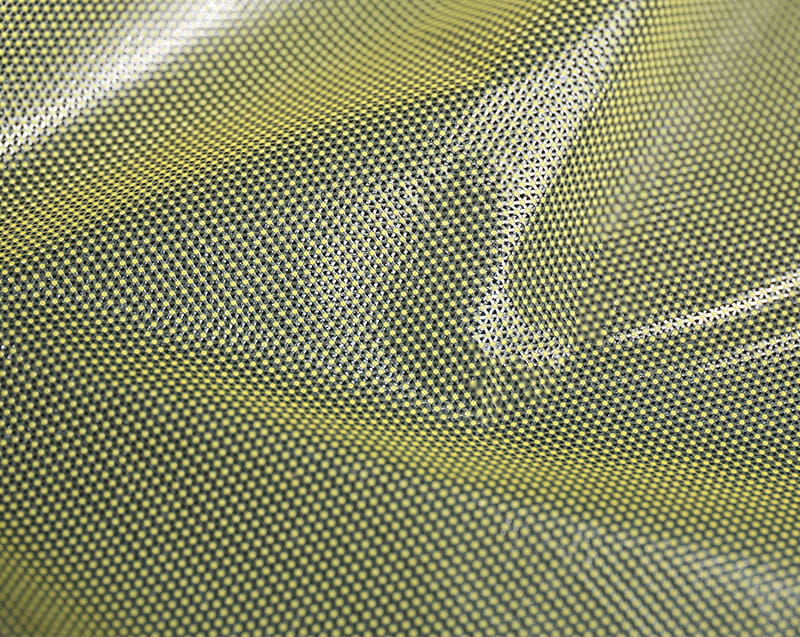

In the textile industry, HMAF is widely used for lamination, creating multi-layered fabrics with enhanced properties such as waterproofing, breathability, and thermal insulation. Applications range from performance sportswear and outerwear to intricate seam bonding that replaces traditional stitching, offering a flatter, lighter, and more aesthetically pleasing finish.

The automotive sector leverages HMAF for its strong, durable, and vibration-dampening bonds. It is used to adhere interior components like headliners, door panels, and seat covers, as well as for acoustic and vibration damping materials, contributing to quieter and lighter vehicles.

In electronics, a specialized Hot Melt Adhesive Film may be used for bonding flexible circuit boards (FPC), adhering thin-film layers in displays, and for encapsulation to protect sensitive components from moisture and shock.

HMAF films are utilized for edge banding in panel processing and for laminating decorative veneers or foils to substrates in furniture manufacturing. In construction, they can be found in specialized window seals and insulation panels.

Choosing the right Hot Melt Adhesive Film depends on a thorough analysis of several factors:

| Factor | Key Considerations |

|---|---|

| Substrates | Compatibility with materials (e.g., plastic, metal, fabric, foam). Surface energy is critical. |

| Activation Temperature | The temperature needed to melt the film; must not damage the substrates. |

| End-Use Environment | Required resistance to heat, cold, humidity, UV light, and chemicals. |

| Bond Strength | Required peel, shear, and tensile strength for the application. |

| Flexibility/Stiffness | Whether the application requires a soft, elastic, or rigid bond line. |

As manufacturers continue to seek cleaner, faster, and more precise bonding solutions, the role of Hot Melt Adhesive Film will only expand. Ongoing research focuses on developing films with lower activation temperatures for heat-sensitive materials, enhanced bio-based formulations, and even stronger performance in extreme environments, ensuring HMAF remains at the forefront of adhesive technology.