The “Sticky” Revolution in Modern Manufacturing

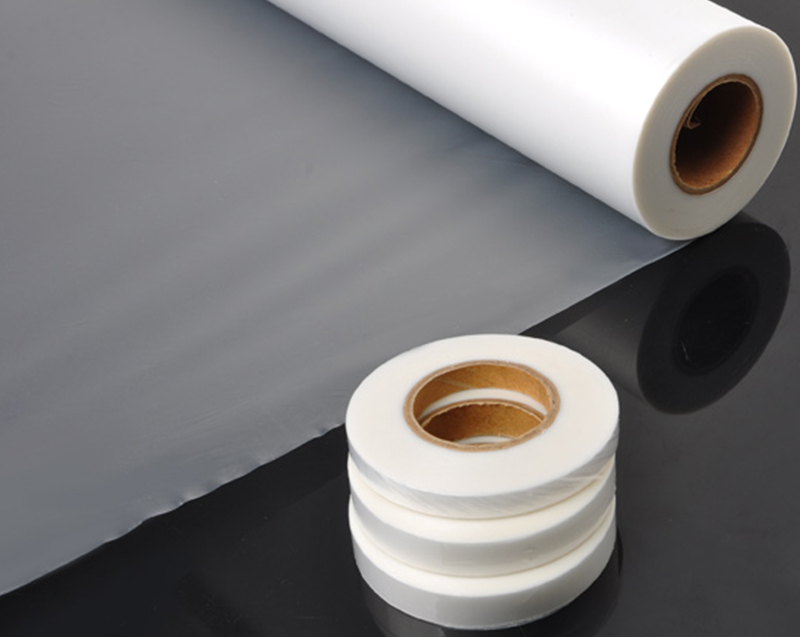

Imagine an adhesive that can bond materials in seconds, is clean to apply, and contains no harmful solvents. This is the reality brought about by Hot Melt Adhesive Film, a true workhorse in modern industry. Far from the messy liquid glues of the past, this innovative material has quietly revolutionized everything from the clothes we wear to the cars we drive.

But what exactly is it, and how does it manage to stick so well?

From Solid to Super-Glue: The Thermoplastic Principle

At its heart, a hot melt adhesive film is a thermoplastic polymer. This means the material is solid at room temperature and is designed to melt into a liquid when heated, then quickly solidify again when cooled—and the solidified state is what forms the powerful bond.

Unlike traditional glues that rely on solvents (liquids that evaporate and carry off harmful volatile organic compounds, or VOCs) to dry and cure, hot melt films are 100% solid. The bonding mechanism is purely physical:

- Activation: The film, typically supplied in rolls or sheets, is placed between the two materials to be bonded. Heat is applied (usually via a heated press or lamination machine) until the film melts.

- Wetting: In its molten state, the low-viscosity adhesive spreads out, or “wets,” the surfaces of the substrates, flowing into tiny crevices to maximize contact.

- Solidification: Once the heat source is removed, the adhesive cools rapidly, solidifying almost instantly to form a durable, high-strength bond.

This rapid setting time is a huge advantage in high-speed manufacturing, as it dramatically speeds up production lines.

The Recipe for Adhesion: Components of the Film

The properties of a hot melt adhesive film are not down to a single material but a carefully engineered blend of components.

The Foundation: Base Polymers

The base polymer is the core ingredient, providing the adhesive’s strength and flexibility. The type of polymer used dictates the film’s final properties:

- EVA (Ethylene-Vinyl Acetate): A versatile, general-purpose choice, often used in packaging and non-structural applications.

- TPU (Thermoplastic Polyurethane): Known for its excellent flexibility, elasticity, and strong adhesion to textiles, making it ideal for performance apparel and footwear.

- PA (Polyamide): Offers superb heat and chemical resistance, favored in automotive and electronics applications.

Supporting Cast: Additives and Modifiers

To fine-tune the performance, other ingredients are added to the polymer blend:

- Tackifiers: These resins increase the “stickiness” or initial grab of the molten adhesive, improving how well it “wets” the surface.

- Waxes: Used to adjust the viscosity (flow rate) and the set time, helping the film cool and solidify faster.

- Plasticizers: Added to increase the film’s flexibility and toughness.

- Antioxidants: Essential for protecting the adhesive from degradation during processing and over its long-term use.

A World Bonded Together: Everyday Applications

The uses of hot melt adhesive film are so widespread that they touch nearly every part of our daily lives, often without us realizing it.

Invisible Bonds in Textiles and Apparel

In the garment industry, this technology is paramount. The film is used for:

- Seamless Garments: Creating smooth, lightweight bonds in activewear and underwear, eliminating bulky stitches.

- Functional Fabrics: Laminating multiple layers of fabric in waterproof jackets (e.g., bonding a face fabric to a breathable membrane) to create durable, water-tight seals.

High-Tech Assembly

In more demanding industries, the film provides clean, reliable joining:

- Automotive: Bonding interior components, sound-dampening materials, and decorative trim, resisting the stress of heat and vibration.

- Electronics: Securing components and providing protective lamination for flexible circuits and display screens.

- Packaging: High-speed sealing of cartons and labels where a fast, strong, and tamper-evident bond is required.

The Hot Melt Adhesive Film represents a triumph of material science, offering a fast, clean, and highly versatile bonding solution that continues to drive innovation across diverse manufacturing sectors.