Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

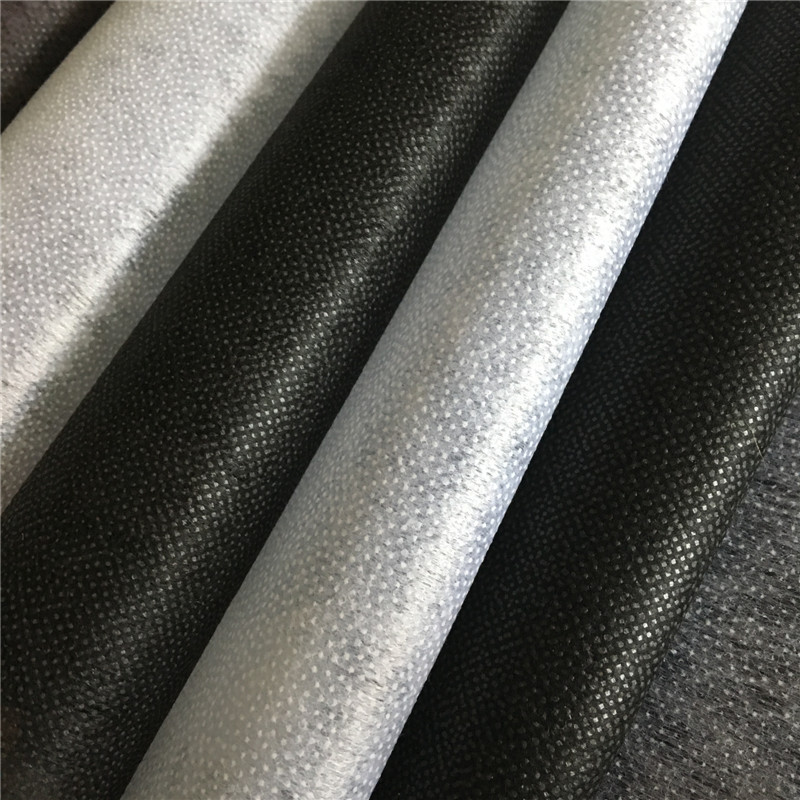

In the vast and ever-evolving landscape of material science, one innovation stands out for its unique combination of versatility, performance, and comfort: Elastic Non-Woven Fabric. This material is a quiet revolution, a testament to how intelligent design can transform everyday products, from the mundane to the highly specialized. Unlike traditional woven or knitted fabrics, non-wovens are created by bonding fibers together through mechanical, chemical, or thermal processes. The addition of elasticity to this structure unlocks a new dimension of functionality, making it a critical component in a myriad of industries.

The story of Elastic Non-Woven Fabric is one of smart engineering. Its creation involves integrating elastic polymers or fibers into the non-woven matrix during production. This can be done in several ways. One common method involves blending elastic fibers, such as spandex or Lycra, with other staple fibers like polypropylene or polyethylene. Another technique uses elastic film laminates or melt-blown elastic webs that are then bonded to other non-woven layers. This structural ingenuity gives the final material its characteristic stretch and recovery. When stretched, the fabric elongates and then returns to its original shape, providing a snug yet gentle fit without losing its integrity. This "memory" is what differentiates it from materials that simply tear or permanently deform under tension.

The applications of Elastic Non-Woven Fabric are surprisingly diverse, touching our lives in ways we might not even realize. Its inherent softness, breathability, and stretch make it a perfect fit for a wide range of products.

In the personal care sector, this material is a true game-changer. It is the silent hero behind the snug and secure fit of disposable diapers and adult incontinence products. The soft, elastic side panels and ear tabs conform to the body's shape, preventing leaks and providing comfort for the wearer. Similarly, feminine hygiene products benefit from the material's gentle stretch and high absorbency, ensuring both discretion and reliability. Its use in medical dressings and bandages is another example of its crucial role, as it allows for a secure fit on joints and other flexible body parts without restricting movement or causing irritation.

The medical and healthcare industry relies heavily on Elastic Non-Woven Fabric for more specialized applications. Surgical gowns and drapes often incorporate elastic non-woven components to provide a secure fit around the neck and wrists, enhancing the barrier protection for medical professionals. Face masks with elastic ear loops are now a ubiquitous example of this material’s importance, providing a comfortable and effective seal against airborne particles. Its use in compression bandages and sports tapes is also a testament to its ability to provide support and stability while allowing for a full range of motion.

Beyond personal and medical care, the reach of Elastic Non-Woven Fabric extends into other areas. In the apparel industry, it is used for comfortable, stretchable interlinings and components in sportswear, providing freedom of movement and a better fit. The automotive industry utilizes it for flexible and durable seating components and interior linings. Even in the world of home furnishings, you can find it in mattress components that require both softness and flexibility.

The widespread adoption of Elastic Non-Woven Fabric is driven by its compelling list of advantages.

Comfort and Fit: The most apparent benefit is its ability to conform to the body's contours, providing a comfortable, non-restrictive fit. This is particularly important for products worn against the skin for extended periods.

Breathability: Many non-woven materials, including elastic varieties, are highly breathable. This allows air to circulate, which is crucial for skin health and reducing moisture buildup.

Strength and Durability: Despite their lightweight nature, these fabrics are engineered to be strong and resistant to tearing. The unique bonding process ensures that they maintain their structural integrity even under repeated stretching.

Cost-Effectiveness: The manufacturing process for non-woven fabrics is often more efficient and less resource-intensive than traditional weaving or knitting, which can lead to a more cost-effective final product.

Versatility: The ability to customize the level of stretch, softness, and absorption during the manufacturing process makes it a highly versatile material that can be tailored to specific product requirements.

In conclusion, Elastic Non-Woven Fabric is more than just a material; it is a fundamental building block of modern innovation. Its ability to provide both comfort and performance has made it an indispensable component in a diverse range of products that improve our health, comfort, and daily lives. As technology continues to advance, we can expect to see even more creative and impactful applications of this remarkable material. The next time you experience the secure fit of a bandage or the gentle stretch of a face mask, you are witnessing the quiet, yet profound, power of Elastic Non-Woven Fabric at work.