Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

Hot melt adhesive film has gained prominence in various industries as a reliable and efficient bonding solution. This innovative adhesive technology is widely recognized for its versatility, environmental friendliness, and ability to provide strong, durable bonds across a range of materials. From textiles to automotive manufacturing, hot melt adhesive films play a critical role in production processes that require precision and durability.

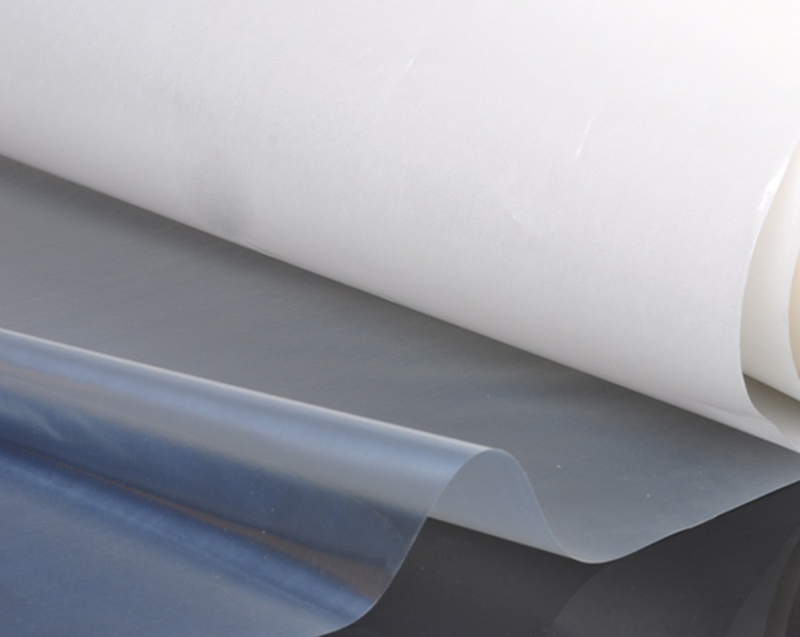

Hot melt adhesive film is a type of solid adhesive that melts upon the application of heat and solidifies upon cooling, creating a strong bond between materials. Typically made from thermoplastic polymers, these films are available in different thicknesses and are tailored for use in specific industries.

Unlike traditional liquid adhesives, hot melt adhesive films come in a solid form, making them easy to handle, apply, and store. This solid nature also eliminates issues such as spillage, drying time, and the need for additional curing processes. When heat is applied, the adhesive film melts, creating a seamless bond between two surfaces. Once it cools and solidifies, the bond becomes permanent, offering high resistance to environmental factors like moisture, heat, and chemicals.

Key Applications of Hot Melt Adhesive Film

Textile and Apparel Industry: Hot melt adhesive films are extensively used in the textile industry for bonding fabrics and assembling garments. Their ability to form flexible and invisible bonds makes them ideal for laminating fabrics, attaching logos or labels, and creating waterproof seams. This application is especially popular in the production of sportswear, outdoor gear, and protective clothing.

Automotive Industry: In the automotive sector, hot melt adhesive films are used for attaching interior trim components, seat cushions, and sound insulation materials. Their strong bonding capacity ensures that components remain securely in place even under extreme conditions such as heat and vibration.

Packaging Industry: Hot melt adhesive films are also applied in packaging, where they are used to seal boxes, laminate packaging materials, and create tamper-evident seals. These films provide a secure and eco-friendly bonding solution, eliminating the need for solvents or liquid adhesives.

Electronics and Appliances: The electronics industry also benefits from hot melt adhesive films. These films are used to bond various components in devices such as smartphones, laptops, and home appliances. Their precision and cleanliness during application make them ideal for sensitive electronic equipment.

Advantages of Hot Melt Adhesive Film

Ease of Use: Hot melt adhesive films are easy to apply and require minimal equipment. The heat-activated process is quick and efficient, reducing production times and costs.

Environmental Friendliness: Unlike solvent-based adhesives, hot melt films do not release harmful chemicals during application, making them a more sustainable option. The absence of solvents also reduces fire hazards.

Durability and Strength: Once applied, the bond created by hot melt adhesive films is strong, durable, and resistant to various environmental stressors, ensuring the longevity of bonded materials.