Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

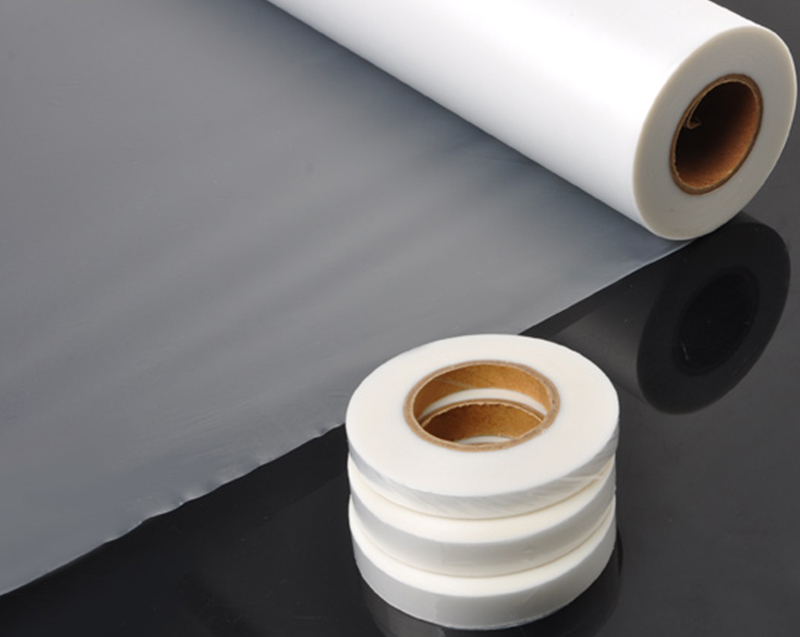

High-density polyethylene (HDPE) tape, a versatile and robust material, plays a crucial role across a multitude of industries due to its unique properties. Unlike standard adhesive tapes, HDPE tape leverages the inherent strength, durability, and chemical resistance of HDPE polymer, making it ideal for demanding applications where conventional materials would fail.

To understand the widespread use of HDPE tape, it's essential to appreciate its core characteristics:

High Tensile Strength: HDPE tape exhibits excellent resistance to stretching and breaking, making it suitable for applications requiring strong binding or reinforcement.

Chemical Resistance: It is largely impervious to a wide range of chemicals, acids, alkalis, and solvents, which is critical in corrosive environments.

Moisture and Weather Resistance: HDPE does not absorb water and can withstand harsh outdoor conditions, including UV radiation, extreme temperatures, and humidity, without significant degradation.

Abrasion Resistance: Its tough surface resists wear and tear, prolonging its lifespan in high-friction applications.

Low Friction Coefficient: The smooth surface of HDPE allows for easy sliding and reduces friction, beneficial in certain mechanical applications.

Non-Conductive: HDPE is an excellent electrical insulator, preventing the flow of electricity.

Flexibility and Conformability: Despite its strength, HDPE tape can be surprisingly flexible and conform to irregular surfaces, aiding in various sealing and wrapping tasks.

These properties translate into a wide array of practical uses across various sectors:

HDPE tape is a staple in the packaging industry for heavy-duty sealing, bundling, and palletizing. Its high tensile strength ensures that packages remain secure during transit, even under stress. It's often used for securing pipes, lumber, and other bulky items, providing a reliable alternative to strapping in many instances.

In construction, HDPE tape finds application in several critical areas. It's frequently used for:

Vapor Barriers: Sealing seams in vapor barrier membranes to prevent moisture intrusion in walls, roofs, and foundations, crucial for energy efficiency and mold prevention.

Duct Sealing: Providing an airtight seal for HVAC ducts, reducing energy loss and improving system efficiency.

Temporary Securing: Holding down protective sheeting or tarpaulins on construction sites due to its weather resistance.

Sub-grade Protection: In some civil engineering applications, it can be used for wrapping or protecting underground pipes and cables from abrasion and chemical attack.

The agricultural sector benefits from HDPE tape's durability and weather resistance. It's commonly used for:

Greenhouse Repair: Patching tears in greenhouse films due to its UV stability and resistance to temperature fluctuations.

Irrigation System Repair: Temporarily sealing leaks in irrigation lines or connecting components in non-pressurized systems.

Crop Support: Providing strong, weather-resistant ties for supporting plants or securing trellises.

In automotive and marine applications, HDPE tape is valued for its resilience to harsh environments:

Wire Harness Wrapping: Protecting wire harnesses from abrasion, moisture, and chemicals within vehicles and boats.

Temporary Repairs: Sealing minor leaks or protecting surfaces from elements in marine environments.

Sound Damping: In some cases, it can be used as a supplementary material for vibration dampening in certain automotive parts.

Across various industrial and manufacturing processes, HDPE tape serves numerous functions:

Masking and Surface Protection: Protecting surfaces from scratches, abrasions, or chemical spills during manufacturing, painting, or assembly processes.

Splicing and Joining: Creating strong, durable splices in various materials, especially where moisture or chemical resistance is required.

Cable and Wire Management: Bundling and organizing cables, offering protection from environmental factors.

High-Wear Applications: Lining chutes or slides to reduce friction and improve material flow due to its low friction coefficient.

HDPE tape is far more than just an adhesive strip; it's an engineered solution that leverages the inherent strengths of high-density polyethylene. Its remarkable combination of tensile strength, chemical and weather resistance, and versatility makes it an indispensable tool across diverse industries. As industries continue to demand more durable, reliable, and resistant materials, the applications of HDPE tape are only likely to expand, cementing its role as a fundamental component in modern engineering and manufacturing.