Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

In the world of textiles and industrial manufacturing, finding materials that can combine durability, flexibility, and ease of use is essential. One such material gaining traction across various industries is PA Hot Melt Mesh Lining Paper . This innovative solution has quickly become a go-to choice for manufacturers looking to enhance their production processes while maintaining high-quality standards.

What is PA Hot Melt Mesh Lining Paper?

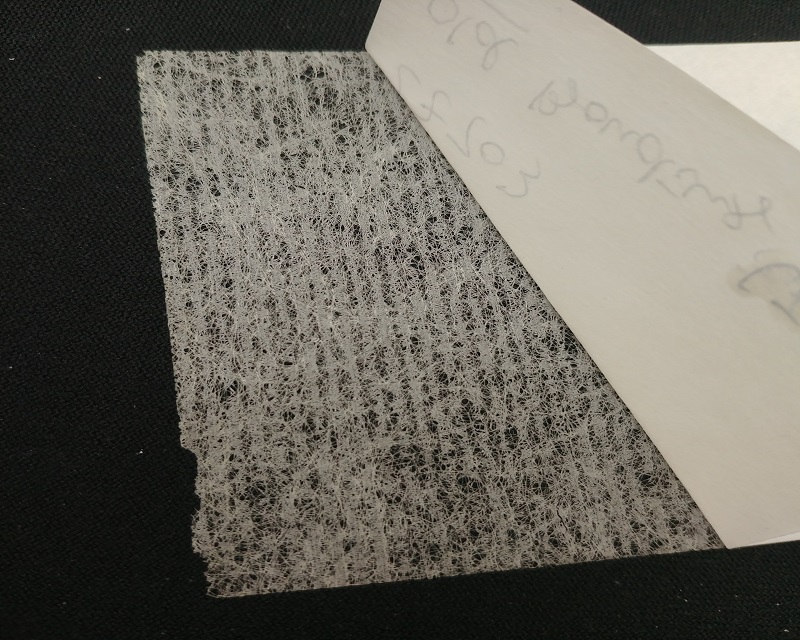

At its core, PA Hot Melt Mesh Lining Paper is a specialized lining material made from polyamide (PA) hot melt adhesives laminated onto a mesh substrate. The mesh structure provides breathability, while the adhesive layer ensures strong bonding capabilities when activated by heat. This combination makes it ideal for applications where both strength and comfort are required.

The "hot melt" aspect refers to the thermoplastic nature of the adhesive, which becomes fluid when heated and solidifies upon cooling. This feature allows for seamless integration into automated production lines, reducing labor costs and increasing efficiency.

Applications Across Industries

One of the standout qualities of PA Hot Melt Mesh Lining Paper is its versatility. Here are some key sectors where this material shines:

Apparel Manufacturing : In garment production, especially for activewear and outerwear, PA Hot Melt Mesh Lining Paper is used to reinforce seams, add structural support, and improve overall durability without compromising on weight or flexibility. Its breathable mesh design ensures that garments remain comfortable even during extended wear.

Footwear Industry : Footwear manufacturers rely on this lining paper to create durable yet lightweight shoe components. From reinforcing toe caps to stabilizing heel counters, the material's ability to bond securely under heat makes it indispensable in creating long-lasting footwear products.

Automotive Interiors : Inside vehicles, comfort and aesthetics are paramount. PA Hot Melt Mesh Lining Paper is increasingly being utilized in automotive interiors for tasks like attaching foam padding to fabric or leather upholstery. Its breathable properties help prevent moisture buildup, ensuring passenger comfort over time.

Home Textiles : From cushions to bedding, this lining paper is also making waves in the home textiles sector. It helps maintain the shape and integrity of soft furnishings while allowing them to remain breathable and easy to clean.

Advantages Over Traditional Alternatives

Compared to traditional lining methods, PA Hot Melt Mesh Lining Paper offers several advantages:

Efficiency : The heat-activated adhesive eliminates the need for messy liquid glues or additional stitching, streamlining the manufacturing process.

Durability : Once bonded, the material forms an incredibly strong connection that resists peeling or delamination, even under stress.

Sustainability : Many formulations of this lining paper are designed with eco-friendly practices in mind, using recyclable materials and minimizing waste during production.