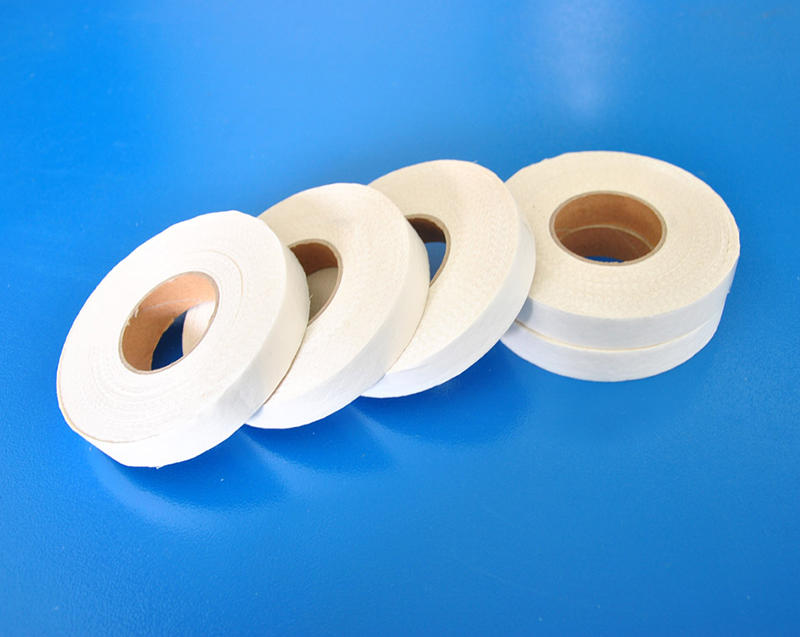

The versatility of Hot Melt Adhesive Net With Paper

Paper and Cardboard: Ideal for packaging applications such as carton sealing, box assembly, and laminating.

Plastics: Bonds well to a wide range of plastics, including polyethylene, polypropylene, PET, PVC, and more, making it suitable for product assembly, product packaging, and labeling.

Wood: Effective for woodworking applications such as edge banding, veneering, and laminating.

Textiles: Useful for bonding fabrics in garment manufacturing, textile labeling, and non-woven assembly.

Foams and Foam-like Materials: Bonds foam materials for insulation, cushioning, and packaging purposes.

Metal: Some formulations can bond to metals, enabling applications in automotive assembly, appliance manufacturing, and construction.

Application Methods: Hot Melt Adhesive Net With Paper can be applied using various methods, including:

Roll Coating: Suitable for continuous applications in industries like packaging and label manufacturing.

Spraying: Enables even coverage over large areas and irregular surfaces.

Extrusion: Commonly used in automated assembly lines for precise application on specific parts or components.

Dot Dispensing: Provides controlled placement for bonding smaller parts or for creating adhesive patterns.

Environmental Conditions: These adhesives can be formulated to withstand different environmental conditions, including:

Temperature Resistance: Options available for both low and high-temperature applications, making them suitable for freezer packaging, automotive interiors, and outdoor signage.

Moisture Resistance: Some formulations offer resistance to moisture and humidity, ensuring durable bonds in environments prone to moisture exposure.

Chemical Resistance: Certain formulations provide resistance to chemicals, oils, and solvents, enhancing performance in demanding industrial environments.

Packaging: Used for sealing, labeling, and assembling packaging materials such as boxes, bags, and cartons.

Automotive: Applied in interior trim assembly, headliner bonding, wire harnessing, and gasket sealing.

Construction: Utilized in woodworking, panel lamination, insulation bonding, and modular construction.

Textiles and Apparel: Employed for bonding seams, attaching labels, and manufacturing non-woven fabrics.

Electronics: Used for component assembly, potting, and wire tacking in electronic device manufacturing.

浙公网安备 33048202000557号

浙公网安备 33048202000557号